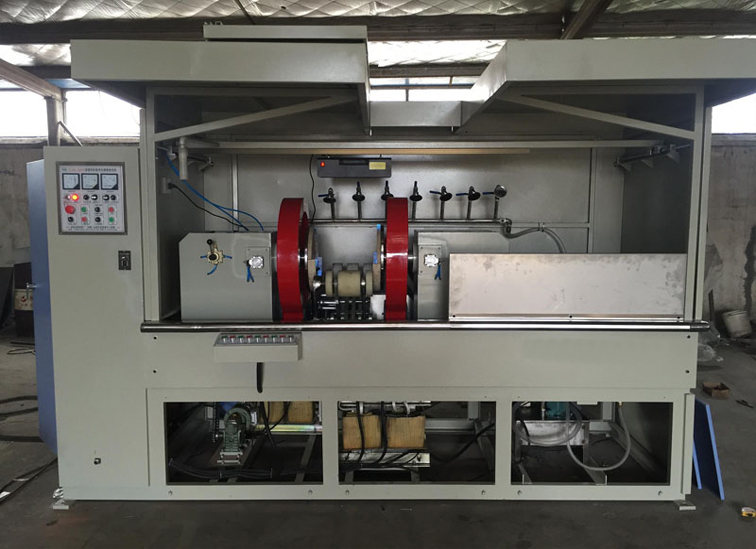

Specification of FDG666 Magnetic particle inspection equipment

1.Equipment composition

--One set of control center (human-machine interface touch screen operation, digital display)

--One set of main machine (including: circumferential and longitudinal transformer, circumferential clamping magnetizing mechanism, screw nut pole spacing adjustment mechanism, etc.)

--one set of magnetic suspension spray agitation recovery system

-- one set of Darkroom system (automatic opening and closing)

--Two sets of longitudinal magnetizing coil and moving device

--Two sets of LED UV light system

--One set of bracket rotating mechanism

2.Test workpiece: drill collar.

3.Equipment capacity:

Test efficiency: 5-8 minutes / piece.

4.The design standard of this machine:

Magnetic particle testing machine (JB / t8290-2011).

5.Main technical indicators:

--Circumferential magnetizing current: AC: 0 ~ 6000a (effective value) continuously adjustable, with power-off phase control;

--Longitudinal magnetization magnetic potential: AC: 0-20000at (effective value) continuously adjustable, with power-off phase control;

--Electrode spacing: 0-15000mm.

--Magnetization principle: electrified, coil method, segmented magnetization.

--Magnetization mode: circumferential magnetization, longitudinal magnetization and composite magnetization can be selected flexibly.

--Operating environment: - 10 ℃ - + 40 ℃, relative humidity ≤ 80%.

--Storage environment: temperature - 20 ℃ - 60 ℃, relative humidity ≤ 70%. No corrosive gas dust and strong high frequency electromagnetic pollution.

--Ultraviolet intensity: the ultraviolet intensity at 380mm away from the workpiece shall not be less than 4000 μ w / cm2.

--Sensitivity test: according to the provisions of JB / t6065-92 standard test piece for magnetic particle testing of the mechanical industry of the people's Republic of China, test with standard a type 2 test piece, with clear display.

--Power supply: three phase four wire, 380V ± 20%, 50Hz, about 250A.

--Inspection surface: cracks and other defects on all surfaces of the workpiece.

--Demagnetization: attenuation type automatic demagnetization.

--Demagnetization time: ≤ 4S.

--Remanence: br ≤ 0.3mt.

--Observation speed of workpiece rotation: 4-6rpm.

--Magnetizing coil: inner diameter 400mm. Electric movement, segmented magnetization.

--Pneumatic clamping: two way clamping, clamping stroke 0-50mm.

--Air supply pressure: 0.4-0.8mp.

--Size of magnetizing power cabinet: 620 * 500 * 1750, size of clamping device: 17000 * 900 * 1400 (excluding darkroom)

--Equipment weight: 4T

6.Running program: manual and automatic.

The automatic program is as follows: feeding, clamping, rotating, spraying, segmented magnetization, rotating observation, demagnetization, unclamp and blanking, (magnetization detection at both ends simultaneously) the whole process is controlled by a small industrial PC. The automatic program can be carried out continuously.