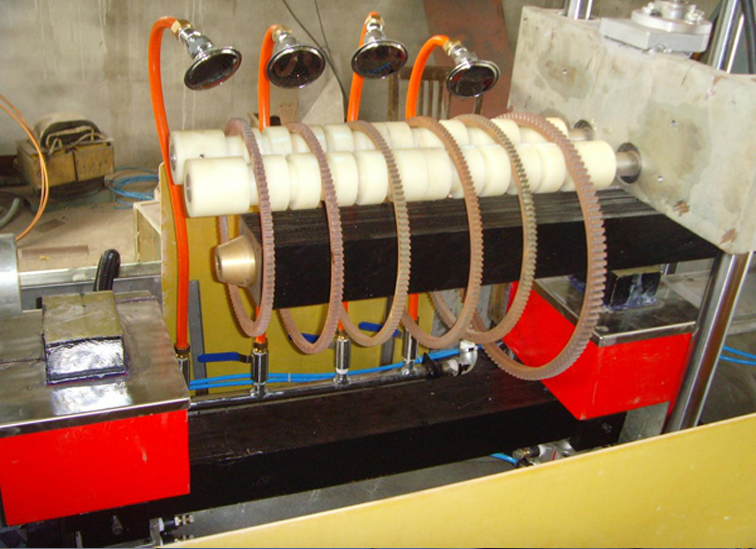

Through the current in the magnetic rod passing through the workpiece, the magnetic field along the circumference direction will be generated on the surface and near the surface of the workpiece, which is used to detect the axial defects along the workpiece; because the workpiece is a ring, the magnetic field generated by the magnetic yoke coil of the machine will generate a secondary induction current along the circumference of the workpiece when passing through the center of the workpiece through the magnetic rod, and the magnetic field generated by the current can be detected Circumferential crack of workpiece. When two kinds of magnetic fields are applied to the workpiece at the same time, due to the phase difference between the circumferential and longitudinal magnetizing currents, a compound rotating magnetic field can be formed on the workpiece surface, and defects in all directions near the surface can be found at one time.

The control circuit adopts the integrated circuit technology, which adjusts the output current of the main circuit by changing the conduction angle of the thyristor. The magnetizing current is continuously adjustable and has the function of power-off phase control. It can be used not only for the continuous method of flaw detection, but also for the remanence method of single direction magnetization.

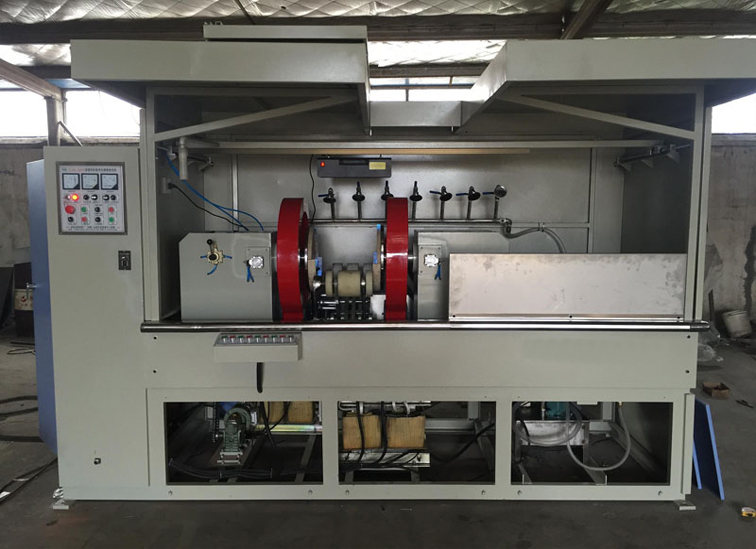

EJW888 Magnetic particle inspection machine specification:

Main technical indicators:

This machine is in accordance with the national standard of the people's Republic of China magnetic particle testing machine < Magnetic Particle Testing > > JB / t8290-2011 national standard.

Input power supply: three-phase four wire 380V ± 10%, 50Hz, 300A.

Temporary load rate: 20%.

Circumferential magnetizing current: AC 0-8000a, continuously adjustable (with power-off phase control).

Longitudinal magnetization ampere turn: AC 0-20000at, continuously adjustable (with power-off phase control).

Demagnetization mode: attenuation type automatic demagnetization.

Demagnetization time: ≤ 3 seconds.

Demagnetization effect: remanence ≤ 2GS.

Principle of magnetization: electrifying and threading.

Electrode spacing: 0-600MM

Magnetization mode: single circumferential magnetization, single longitudinal magnetization and composite magnetization.

Observation speed of workpiece rotation: 4-6rpm.

Yoke coil: inner diameter: 300 mm.

UV intensity: the intensity at 380mm from the surface of the workpiece to the UV bulb shall not be less than 1000uw / cm2.

Air supply pressure: 0.4-0.8mp.

Service environment: temperature - 10 ℃~ +40 ℃, relative humidity ≤ 80%.

Storage environment: temperature - 20 ℃ ~ + 60 ℃, relative humidity ≤ 70%, no corrosive gas dust and strong high-frequency electromagnetic pollution.

Sensitivity test: according to the provisions of standard test piece for magnetic particle flaw detection in JB / t6065-92 of the people's Republic of China, test with 15 / 50 A-type test piece, and display clearly in any direction of the workpiece.

Detection process:

Running program: manual and automatic.

Automatic program:

Manual feeding - threading - rotation - spraying - magnetization - rotation - manual observation - demagnetization - Loosening - blanking.