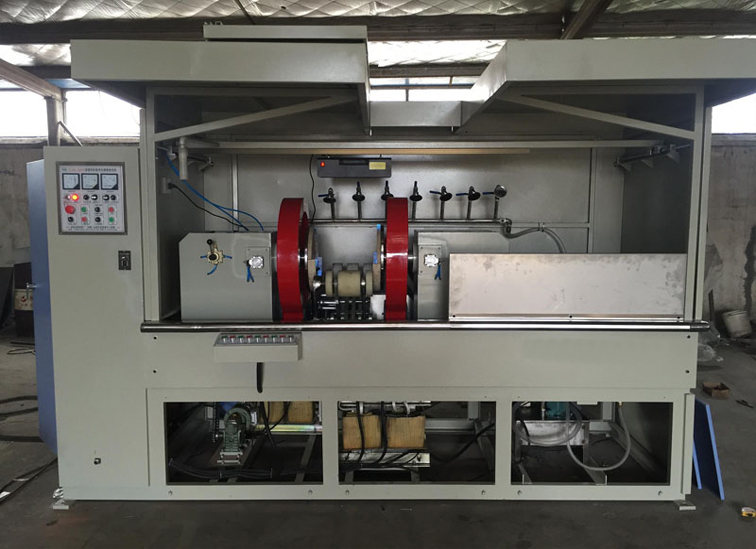

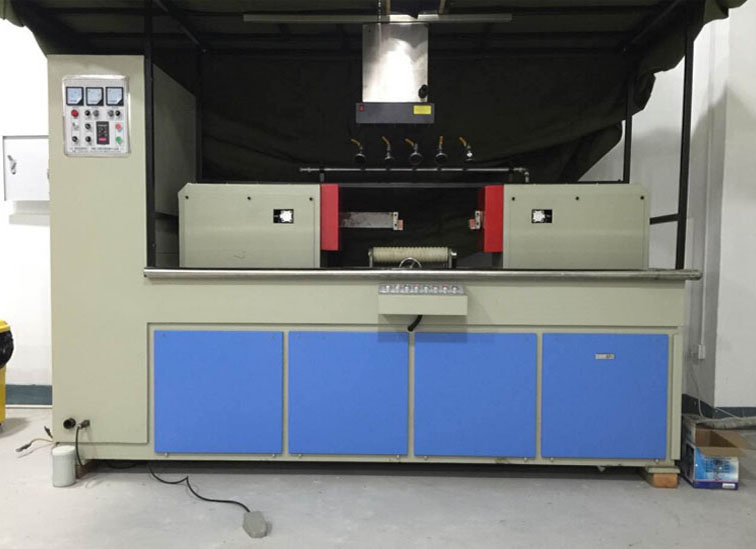

EDG666 fluorescent magnetic particle testing machine is an electromechanical combined semi-automatic magnetic particle testing equipment, which is composed of power control system, clamping magnetization device, magnetic suspension system, etc. it is suitable for wet magnetic particle testing of the surface and near surface of the semi axle, tube and bar parts made of ferromagnetic materials caused by casting, forging, processing, fatigue and other reasons Micro defects.

The equipment adopts two operation modes, manual and automatic, and is centrally controlled by OMRON PLC. In manual mode, the single step operation of each function can be carried out; in automatic mode, the equipment automatically executes PLC internal program. After the workpiece is loaded and clamped, press the start button to realize a series of actions such as workpiece rotation spray magnetization. Loosen the workpiece after manual demagnetization. Two groups of special-shaped coils are used in the circumferential magnetization and the longitudinal magnetization, which have good magnetization effect. AC magnetization with power-off phase control has good remanence stability, which is suitable for both continuous method and remanence method. The compound magnetization forms a rotating magnetic field on the workpiece, which shows the magnetic trace at one time, and has a high working efficiency.

Specification of EDG666 Fluorescent Magnetic particle inspection equipment

1. Equipment composition

--One set of control center (human-machine interface touch screen operation, digital display)

--One set of main machine (including: pneumatic clamping mechanism, closed-circuit yoke longitudinal magnetizer, circumferential magnetizer, etc.)

-- One set of magnetic suspension spraying system

--One set of LED UV light system

--One set pf Darkroom system

--One set of Omron (PLC) control system

--One set of lifting bracket rotating mechanism

2. Test workpiece: coupling ≤ 450mm.

3. Equipment capacity

Operation time: > 600 hours / month.

Detection efficiency: (10-30 seconds / piece, depending on the time required for different workpieces, and related to the proficiency of the operator, except for the observation time).

Inspection requirements: inspect the internal and external surface of the workpiece and the near surface for cracks and other minor defects caused by machining and fatigue.