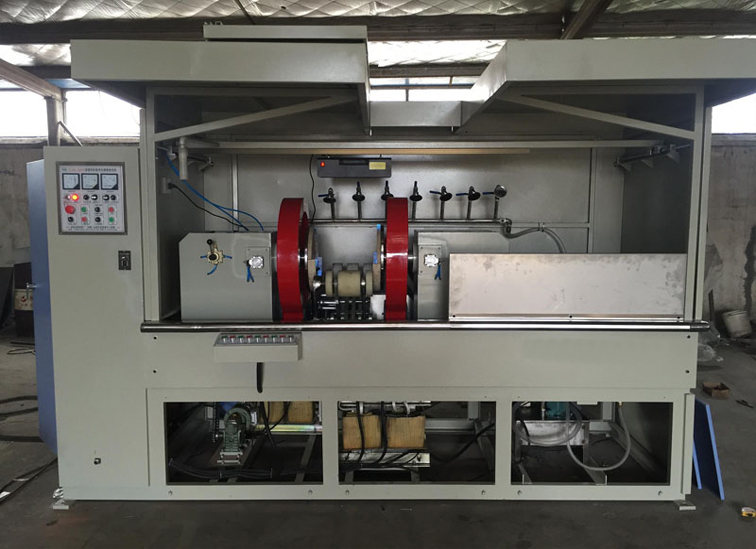

DDG-666 fluorescent magnetic particle testing machine is an electromechanical combined semi-automatic magnetic particle testing equipment, which is composed of power control system, clamping magnetization device, magnetic suspension system, etc. it is suitable for wet magnetic particle testing of the surface and near surface of crankshaft.

DDG666 Magnetic particle inspection machine specification:

1.Equipment composition:

--Control center (HMI touch screen operating system, digital display).....................one set

--Main machine (including: circumferential and longitudinal transformer, longitudinal magnetizer, circumferential clamping magnetization mechanism, screw nut pole spacing adjustment mechanism, etc.)----------------------------------------------------------- one set

--Pneumatic clamping mechanism----------------------------------------------------- one set

--Bracket rotating mechanism --------------------------------------------------------- One set

--Coil extension mechanism ----------------------------------------------------------Two sets

--Magnetic suspension spray recovery system -------------------------------------one set

--Totally closed darkroom system --------------------------------------------------- one set

--Led UV light system ------------------------------------------------------------------one set

2. detection workpiece: crankshaft.

3. Equipment capacity:

Flaw detection time: 15-25 seconds / piece, except observation time.

4.The design standard of this machine:

< Magnetic Particle Testing > > JB / t8290-2011 national standard.

5. Main technical indicators:

--The circumferential magnetizing current AC: 0-6000a (effective value) is continuously adjustable, with power-off phase control (no missing detection).

--Longitudinal magnetization magnetic potential AC: 0-20000at (effective value) continuously adjustable, with power-off phase control (no missing inspection).

--Electrode spacing: 0-1500mm.

--Magnetization principle: power on, coil method.

--Magnetization mode: circumferential magnetization, longitudinal magnetization and composite magnetization can be selected flexibly.

--Operating environment: - 10 ℃ - + 40 ℃, relative humidity ≤ 80%.

--Storage environment: temperature - 20 ℃ - 60 ℃, relative humidity ≤ 70%. No corrosive gas dust and strong high frequency electromagnetic pollution.

--Ultraviolet intensity: the ultraviolet intensity at 380mm from the workpiece is more than 4000 μ w / cm2.

--Sensitivity test: according to the provisions of JB / t6065-92 standard test piece for magnetic particle testing of the mechanical industry of the people's Republic of China, test with Standard No. 2 type a test piece, with clear display.

--Power supply: three phase four wire, 380V ± 20%, 50Hz, about 250A.

--Inspection surface: cracks and other defects on all surfaces of the workpiece.

--Demagnetization: ac20000-0 (effective value) attenuation type automatic demagnetization.

--Remanence: br ≤ 0.2Mt.

--Observation speed of workpiece rotation: 4-6rpm.

--Magnetizing coil: inner diameter 450mm. The air cylinder automatically extends when the coil moves.

--Pneumatic clamping: clamping stroke 0-100mm. The stroke of the coil extending out of the cylinder is 0-350mm

--Air supply pressure: 0.4-0.8mp.

--Size of magnetizing power cabinet: 620 * 500 * 1750, size of clamping device: 2800 * 800 * 1400 (excluding darkroom)

--Equipment weight: 2T

6.Running program: manual and automatic.

The automatic program is: feeding - clamping (magnetizing coil forward) - spraying - magnetizing - (magnetizing coil retracted) - rotating observation (magnetizing coil forward) - demagnetizing - unclamp - blanking. The whole process is controlled by a small industrial PC. The automatic program can be carried out continuously.