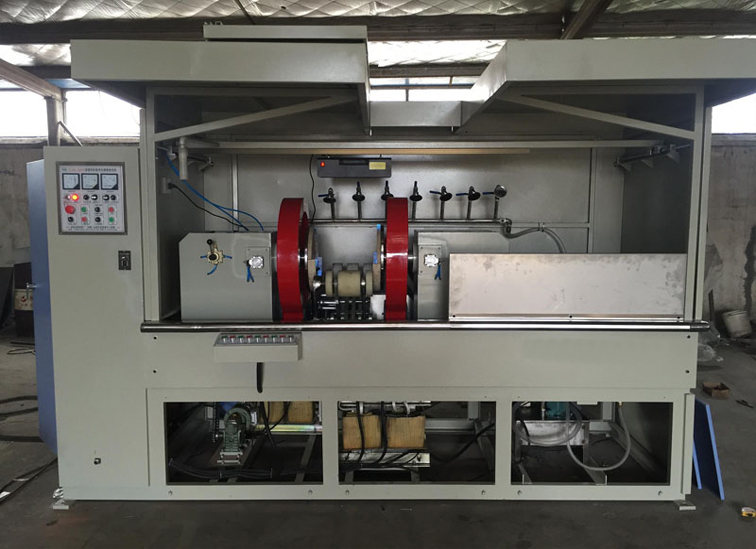

Equipment Overview:

Czq-666 type three-phase full wave DC magnetic particle testing and ultra-low frequency demagnetization machine adopts the mechanical and electrical vertical structure, and the power control cabinet and the clamping magnetization bed are separated independently. The direct energizing method of AC and DC magnetizing power supply is adopted for the circumferential magnetization, which produces the circumferential magnetic field on the workpiece and detects the axial crack defects of the parts. The longitudinal magnetization adopts the method of AC and DC double magnetization coil plus magnetic field (two groups of coils in total, to ensure the one-time magnetization of long workpiece) The longitudinal magnetic field is generated on the workpiece to detect the circumferential crack defects of the parts. The circumferential and longitudinal composite magnetization can detect the crack defects of the parts in an all-round way. The weekly, longitudinal AC and DC magnetization power supply is also switched through high-power pneumatic transfer switch (switching by using the central touch screen operation mode), so as to realize the composite magnetization of the weekly DC, longitudinal AC or the weekly AC and longitudinal DC and the independent magnetization detection of the weekly and longitudinal.

CZQ666 Magnetic particle inspection equipment adopts man-machine interface system to conduct man-machine dialogue. Through the single-chip microcomputer system, the parameters such as magnetizing current, magnetizing time, demagnetizing current and demagnetizing frequency are set and displayed digitally. The accuracy error of magnetizing current is less than ± 5%, which greatly improves the detection accuracy. PLC is used for centralized control of the equipment. All switches (button switch, detection switch, etc.), executive action, logic interlock, process flow, etc. of the equipment are completed by PLC, which can carry out single-step control of each function action, or carry out automatic program control of the equipment detection process flow, and adjust the automation timely according to the user's requirements Controlled process flow procedure.

1. Equipment name, quantity and purpose:

1.1. Equipment name: czq-6000 microcomputer controlled AC / DC (three-phase full wave DC, ultra-low frequency demagnetization) fluorescent magnetic particle flaw detector;

1.2 application: used to detect the surface and near surface defects of various workpieces such as shafts, pipes, bars, etc.

2. Equipment design and manufacturing basis:

2.1. According to the requirements of magnetic particle testing process and the technical specifications for bid invitation.

2.2. According to Hb / z72-98; JB / t8290-2011; and other standards.

2.3 implement the design procedure documents of magnetic particle flaw detector according to IS09001 system.

2.4. The equipment shall meet the requirements of MH / T 3008-2012 and ASTM 1444-2012.

2.5. The equipment complies with the MT for aircraft NDT (mh-t 3008-2004).

3. Equipment composition and supporting devices:

3.1. one set of czq-6000 control system

3.2. One set of DC: 0-6000a three-phase full wave DC magnetizing power supply

3.3. one set of AC: 0-6000a magnetizing power supply

3.4. one set of czq-6000 mechanical bed

3.5 two sets of high power transfer switch system

3.6. One set of magnetic suspension spray and recovery system

3.7 one set of fluorescent detection system

3.8. one set of darkroom