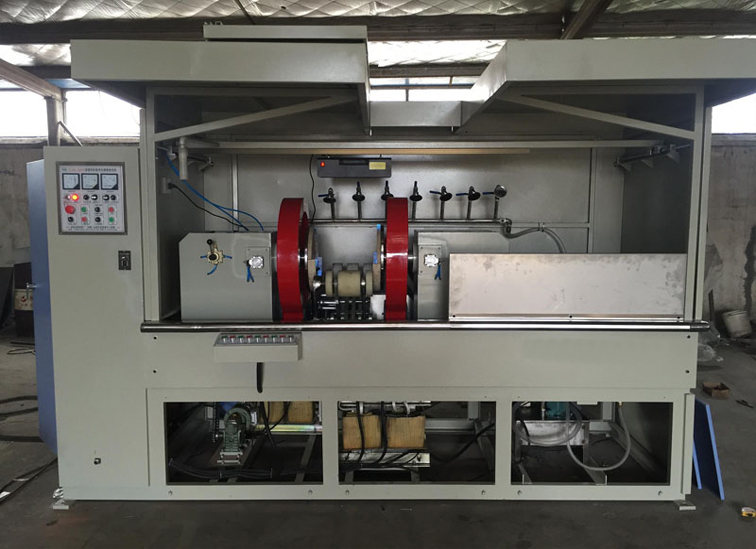

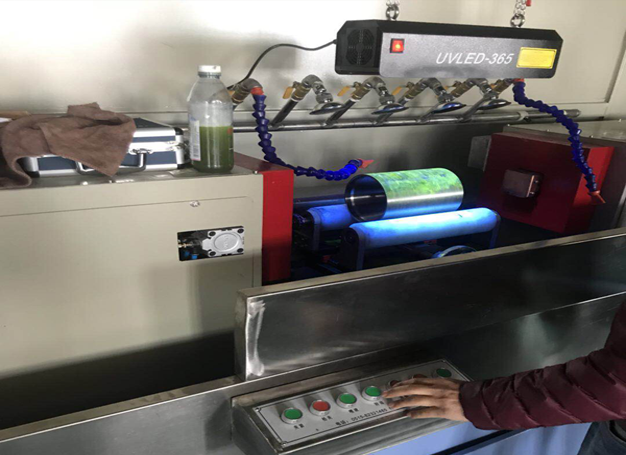

CJW666 magnetic particle testing machine is applicable to the crack detection equipment of bars, pipes, castings, bearings and various kinds of workpieces of ferromagnetic materials. It can conduct circumferential, longitudinal, composite magnetization and demagnetization for workpieces, and the circumferential, longitudinal and composite are all equipped with power-off phase control. The continuous method is used for flaw detection to display magnetic traces in all directions. This machine is controlled by PLC, with all-round magnetism and programmable function. It can automatically realize workpiece rotation → spray magnetic suspension → stop rotation → stop spraying liquid → workpiece clamping → coil moving → section magnetization → observe magnetic trace → demagnetization → manual blanking.

CJW666 Magnetic particle inspection machine specification:

1. Magnetized magnetic potential

The circumferential magnetizing current (power on through the bar) AC: 0-6000a (effective value) is continuously adjustable, with power-off phase control (no leakage detection).

Longitudinal magnetizing current (coil) AC: 0-18000a (effective value) continuously adjustable, with power-off phase control (no missing inspection).

2. Electrode spacing: 0-700mm.

3. Magnetization principle: electrifying and threading.

4. Magnetization mode: circumferential magnetization, longitudinal magnetization and composite magnetization can be selected flexibly.

5. Demagnetization mode: attenuation type automatic demagnetization.

6. Demagnetization effect: remanence of workpiece after demagnetization ≤ 0.2Mt.

7. workpiece operation: the groove wheel mechanism is used for workpiece feeding, magnetization, spraying magnetic suspension, observation and other workpiece conversion.

8. air source pressure: 0.4~0.8 Mpa (supplied by the user).

9. Led ultraviolet intensity: 380 mm away from the light source, ≥ 4000 μ w / cm2.

11. Power supply: 380V, 50Hz, > 250A.

12. Sensitivity test: according to the mechanical industry standard of the people's Republic of China JB / t6065-92 standard test piece for magnetic particle testing, test with Standard No. 2 type a test piece, with clear display.

13. Inspection surface: cracks and other defects on all surfaces of the workpiece.

14. Use environment: - 10 ℃ - + 40 ℃, relative humidity ≤ 80%.

15. Storage environment: temperature - 20 ℃ - 60 ℃, relative humidity ≤ 70%. No corrosive gas dust and strong high frequency electromagnetic pollution.

16. Process flow: manual feeding - threading (clamping) - rotary spraying - magnetization - Rotary observation - demagnetization and shrinking - blanking (automatic and manual gears)